Research

Advancing Sustainable Technologies in Materials, Manufacturing, Energy & AI-Driven Simulations.

Innovation Projects

Mechanistic Solutions

AI & ML Based Solutions

Multiscale Ductile Damage in Metals & Alloys

Ductile damage in metals is the main focus of the research. My research group is involved in understanding and developing multiscale computational frameworks for materials undergoing ductile deformation and failure. We have investigated single and dual phase alloys in this context and developed computational frameworks to simulate ductile damage at various length scales.

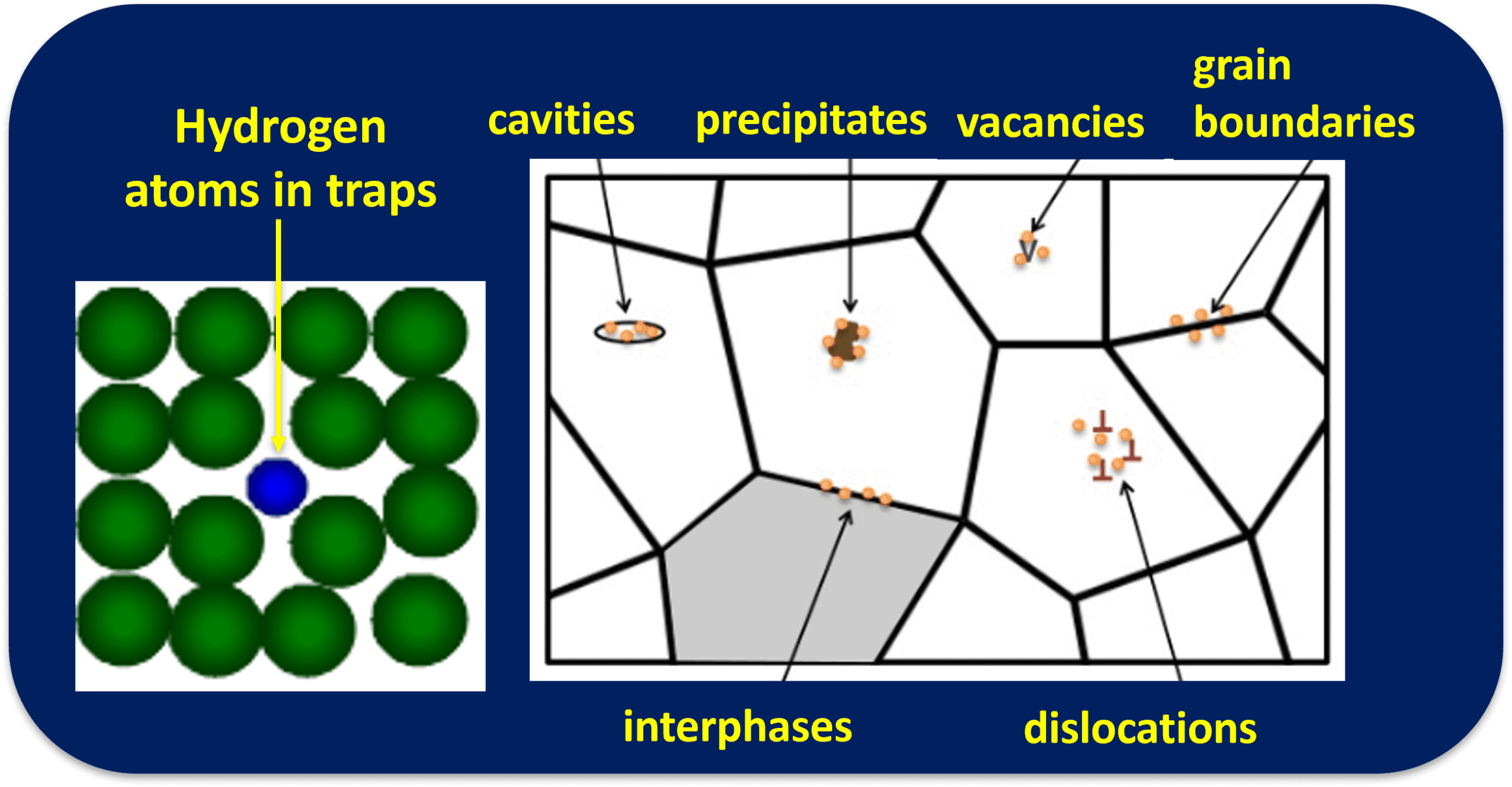

Effect of Hydrogen on Plastic Slip Evolution in Poly-crystalline 316 Austenitic Stainless Steel

Hydrogen–Defect Interaction in Austenitic Stainless Steels

This crystal plasticity study reveals how hydrogen influences void growth and fracture in single-crystal austenitic steel. Results show that hydrogen initially suppresses void growth but later enhances it as deformation localises, with effects strongly dependent on stress triaxiality and Lode parameter — advancing our understanding of hydrogen embrittlement at the microscale.

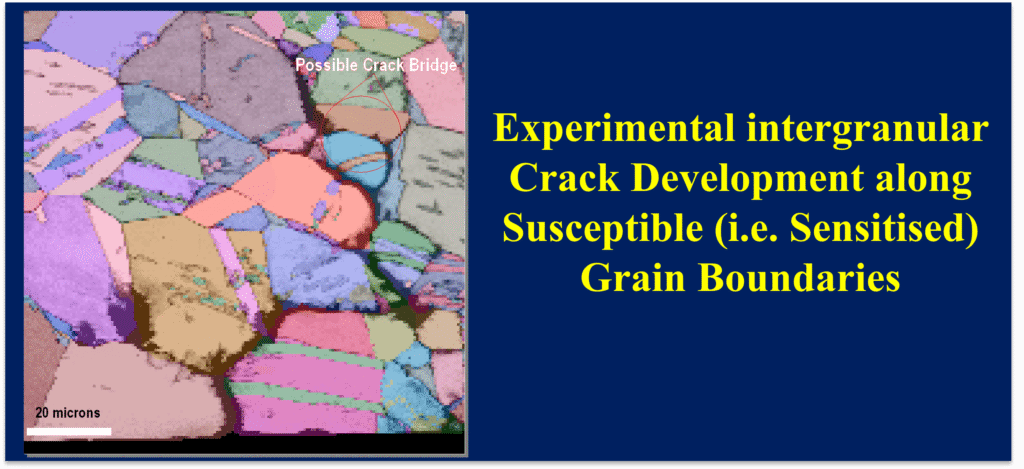

Intergranular Stress Corrosion Cracking in 304 Austenitic Stainless Steel in Acidic Environment

Stress Corrosion Cracking

Stress corrosion cracking is a common failure mode for steels and other high strength alloys in corrosive environments. The aim of this research is to understand underlying physical mechanisms of stress corrosion cracking in steels and develop multiscale computational framework by incorporating these physical mechanisms for better predictions.

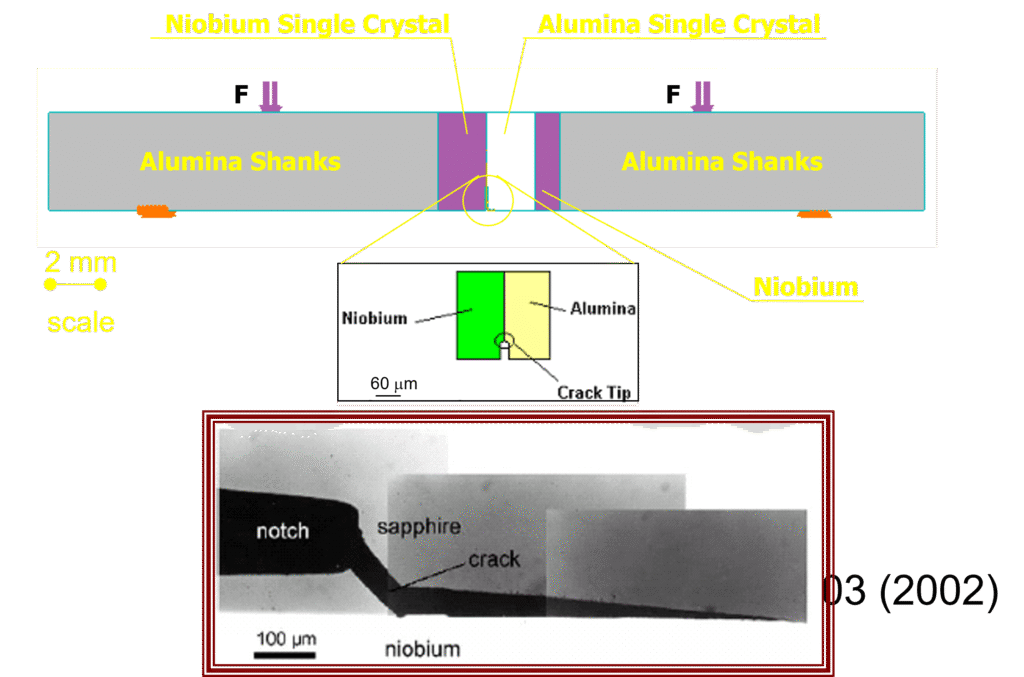

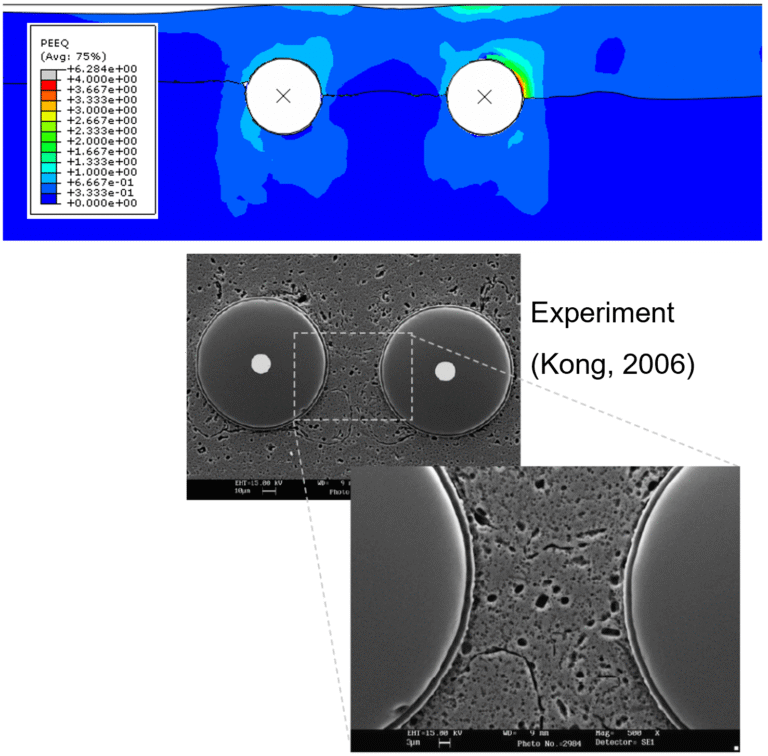

Metal/Ceramic Interface Fracture

Metal/ceramic interface fracture of niobium/alumina bicrystal interface had been studied at Max-Planck Institute for metal research, Stuttgart, Germany since last three decades. It was found that fracture energy of the system changes in some case by 20 times for different orientations of the bicrystal specimen. In this work a length scale bridging procedure was proposed to simulate the interface fracture of niobium/alumina bicrystal specimens.

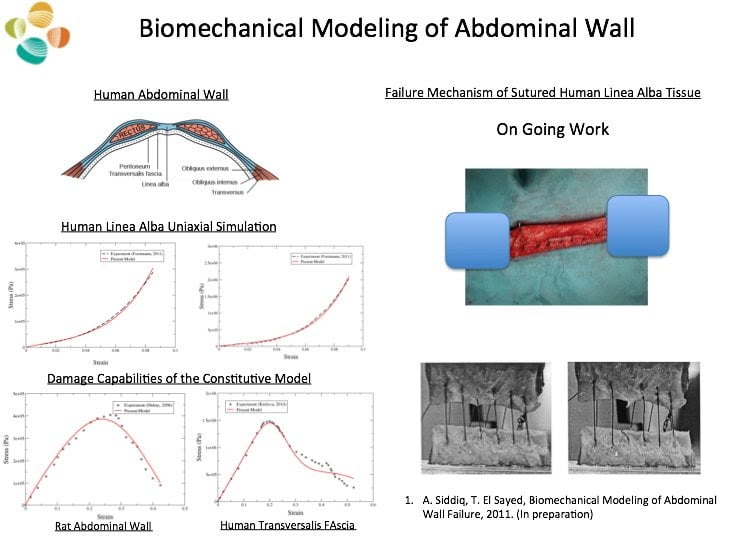

Soft Biological Materials

This research focuses on developing computational frameworks for soft biological materials to predict deformation and failure during different biomechanical activities.

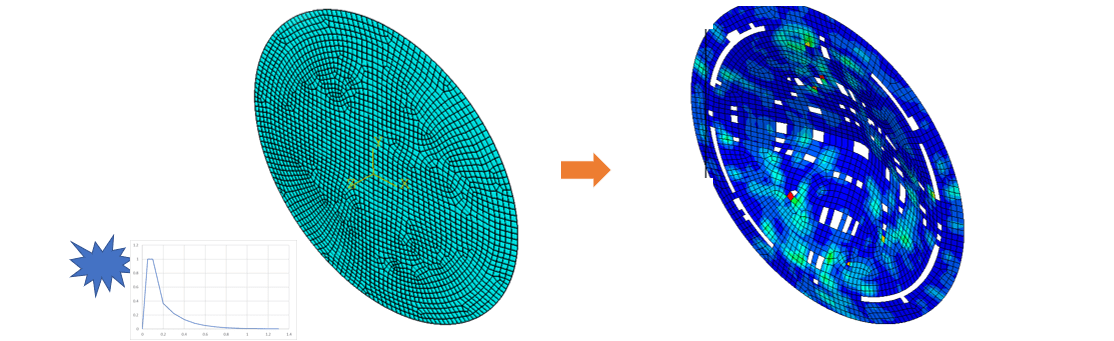

Fibre Reinforced Composite Damage

This research has focussed on state of the art computational methods such as finite element methods and peridynamics to predict the deformation and failure in composites. We deal with wide variety of composites, such as fibre reinforced composites, metal/matrix composites, syntactic foams, etc.

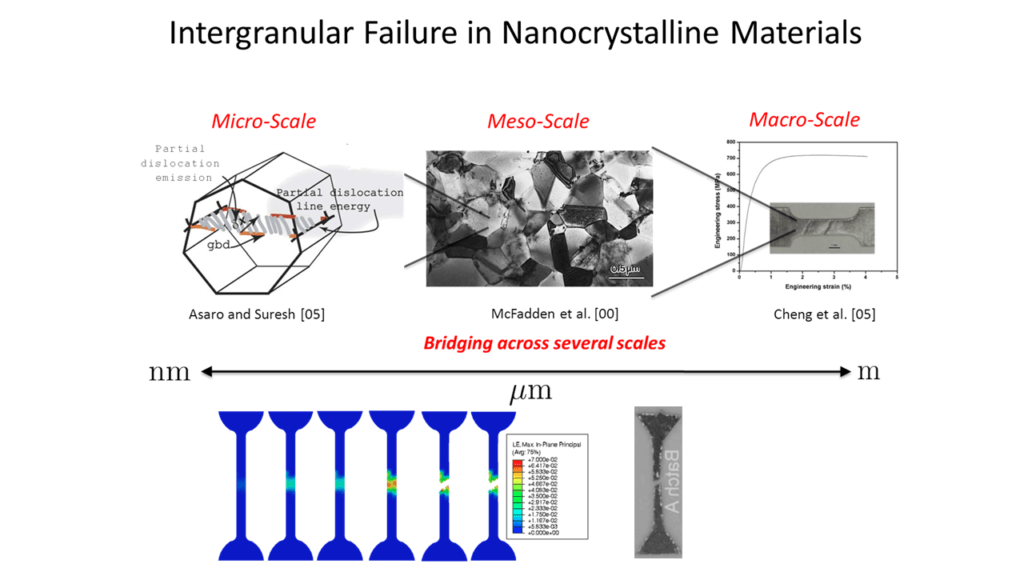

Nanocrystalline Materials

This research focussed on developing a multiscale constitutive model for nanocrystalline materials to predict the deformation and failure at microscale by taking into account loading rates and underlying physics in a phenomenological manner.

Additive Manufacturing and Ultrasonic Consolidation

This research explores advanced metal manufacturing processes, focusing on laser-assisted 3D printing and ultrasonic consolidation. The study investigates how process parameters such as scan speed, laser power, and temperature influence residual stresses, distortions, and microstructure evolution during laser melting and solidification. In parallel, ultrasonic consolidation is modelled across multiple length scales to capture surface and volume softening effects, enabling the embedding and optimisation of fibres and sensors within metallic components.

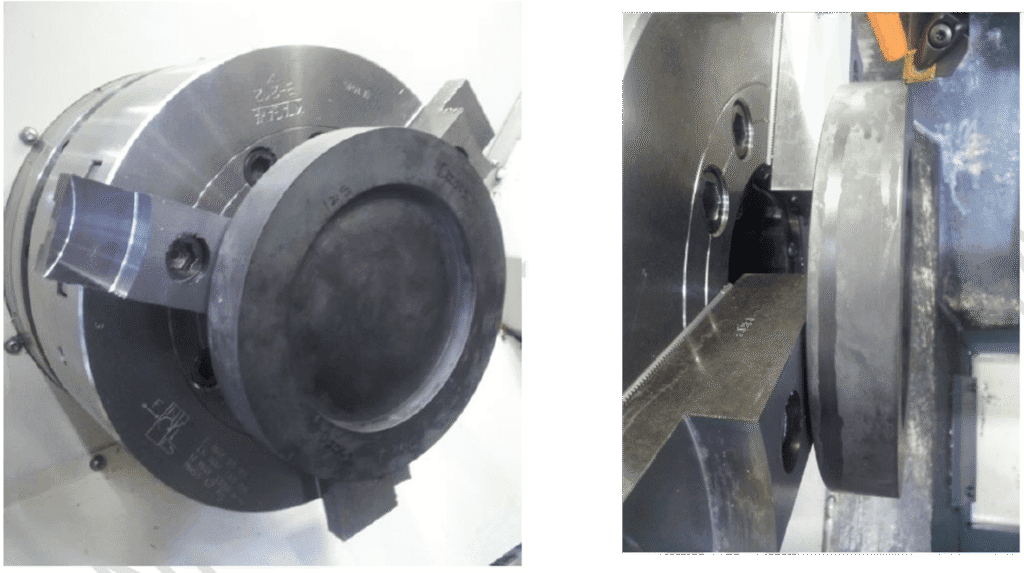

Subtractive Manufacturing (Machining)

This research aimed at understanding and developing computational modes for subtractive manufacturing, i.e. material removal through cutting. Work has been focussed on different materials, for example surface defect machining of silicon by considering the high-pressure phase transformation (HPPT). Other works involved machining of nickel based super alloys to understand the residual stress relaxation of the forged and quenched components.

Metal Forming Processes

This research has focused on understanding multiscale deformation and failure behaviour of materials during conventional and unconventional forming processes. Some examples of the processes under investigation include sheet metal forming, incremental sheet forming, extrusion, and wire drawing. Experimental investigation are then used to develop computational frameworks for better predictions.

Porous Shape Memory Alloys

This work presents a two-phase constitutive model capturing the pseudoelastic and pseudoplastic behavior of porous shape memory alloys (SMAs). The model combines dense SMA and porous plasticity phases, enabling simulation of deformation, transformation, and failure under tension and compression. Validated through finite element simulations and experiments, it provides insights into the deformation and fracture mechanisms of porous NiTi alloys, supporting their design for lightweight and biomedical applications.

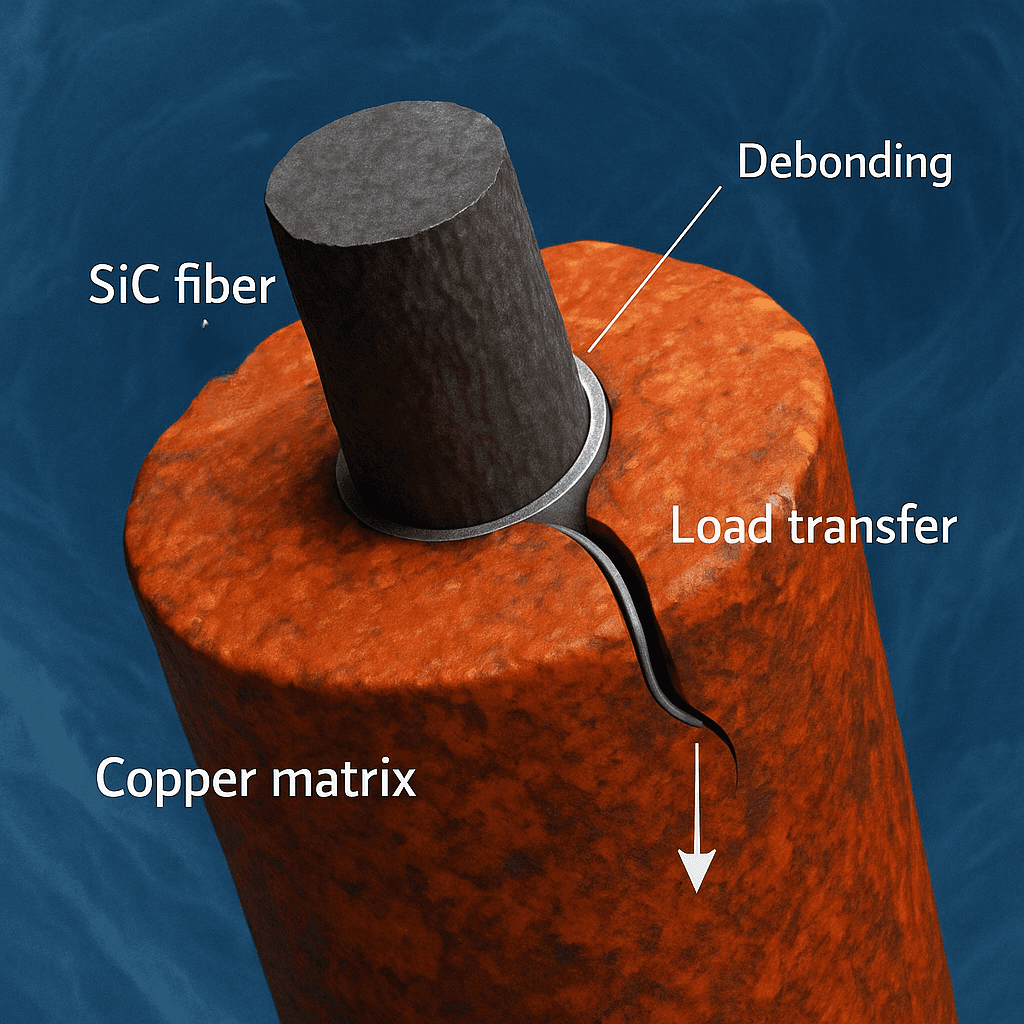

Fiber–Matrix Interface Modelling

This study investigates the mechanical behavior of a copper matrix composite reinforced with silicon carbide fibers through fiber push-out experiments and cohesive zone finite element simulations. The research demonstrates how matrix plasticity and interfacial bonding—enhanced by titanium coatings—govern debonding, sliding, and overall load transfer at the interface. The combined experimental–computational approach accurately captures nonlinear push-out responses and provides insight into interfacial damage mechanisms in metal matrix composites.

Data-Driven Finite Element Method

This research introduces a data-driven finite element method (DDFEM) that eliminates the need for conventional constitutive models by directly using experimental or molecular data to predict deformation and failure. The framework incorporates multiple state variables—such as stress, strain, strain rate, degradation, and anisotropy—and demonstrates strong predictive accuracy across applications ranging from nanomaterials and biomaterials to composites. This approach bridges experimental data and computational mechanics, accelerating reliable materials modelling without parameter fitting.

Metastable β Titanium Alloys

This research advances understanding of deformation and damage in metastable β titanium alloys such as Ti-10V-2Fe-3Al through crystal plasticity modelling and finite element simulations. A novel constitutive framework captures the interplay of slip and stress-induced martensitic transformation, revealing how transformation accommodates strain and inhibits void growth. The integrated studies provide new insights into the mechanisms that govern strength, ductility, and fracture resistance in high-performance β-Ti alloys.

Magnesium Alloys

This research advances next-generation magnesium alloys through interface engineering and ultrasonic processing. Semi-coherent rare-earth intermetallics such as Al₈Mn₄Y strengthen Mg matrices by reducing boundary cracking, while ultrasonic-assisted methods refine grains and enhance weld strength with minimal energy input. Together, these innovations enable lightweight Mg structures with exceptional strength, ductility, and thermal stability.

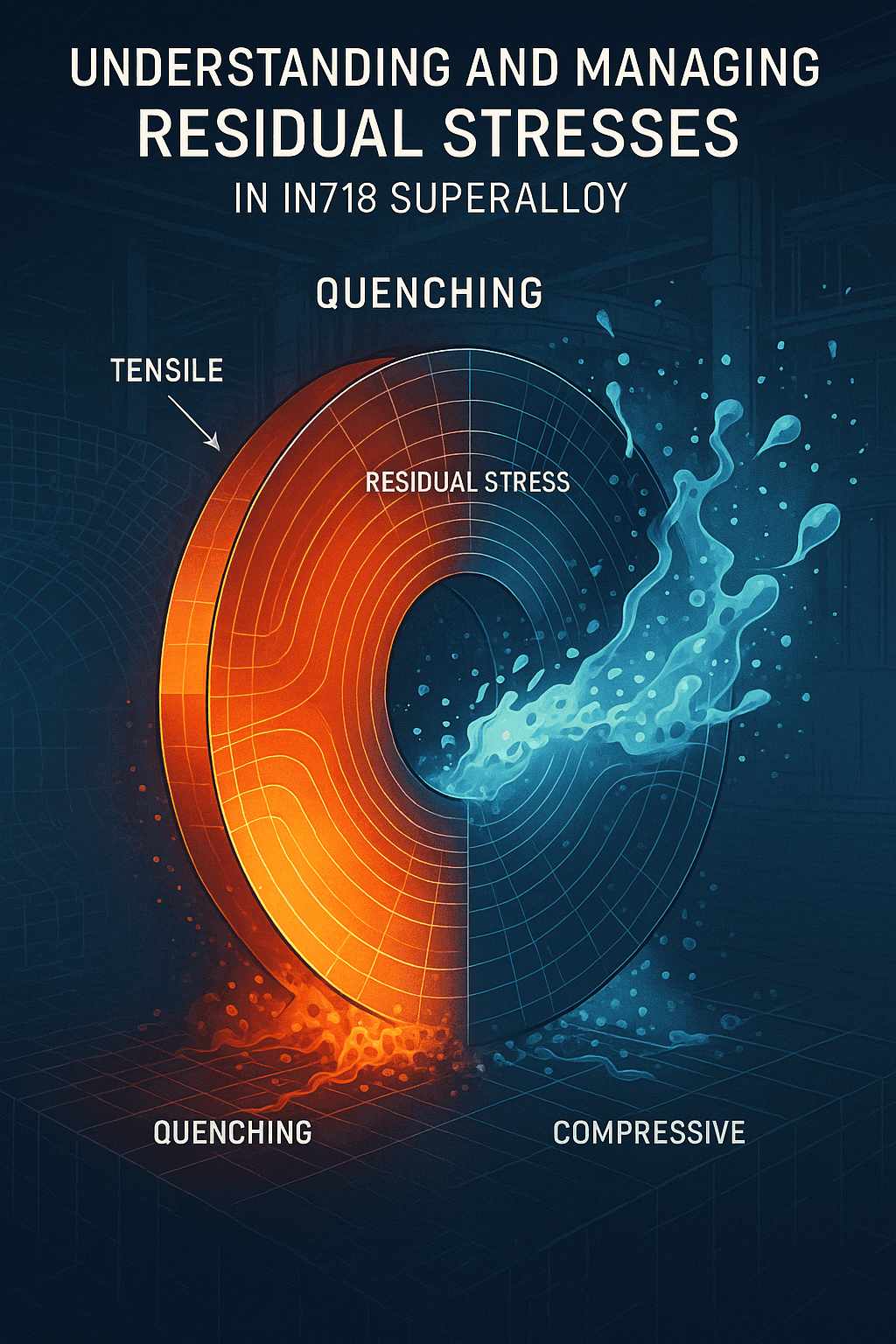

Understanding and Managing Residual Stresses in IN718 Superalloy

Residual stresses, locked-in forces from manufacturing, can cause distortion or early failure but can also improve fatigue life. In this work, we modelled and measured residual stress and distortion in quenched IN718 discs. Experiments at AFRC were combined with finite element simulations to understand heat transfer, quenching, and machining-induced relaxation. The results guide right-first-time manufacturing of high-value components.

Repair Strategies for Wind Turbine Blades

This study investigates repair techniques for wind turbine blades, combining insights from literature, industrial interviews, and case studies. It identifies a lack of standardisation in blade repair management and proposes a structured workflow and asset integrity framework aligned with ISO 55000 principles. The findings support safer, cost-effective, and longer-lasting operation of wind energy assets through improved inspection, repair, and maintenance strategies.

For more details

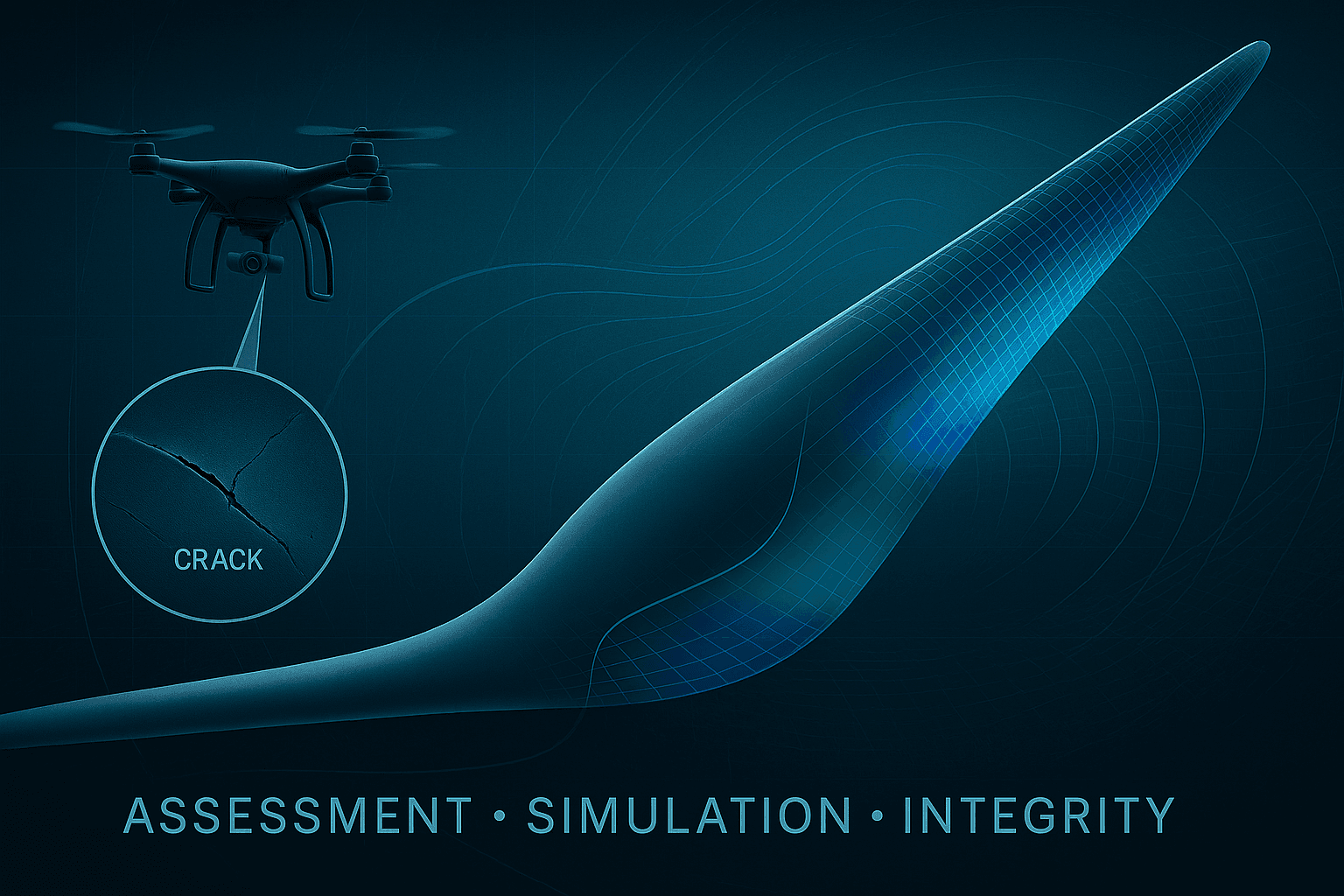

Wind Turbine Blade Integrity

This project develops a fitness-for-service (FFS) methodology for wind turbine blades, integrating aeroelastic simulations and finite element analysis. Using a validated model of a Clipper Liberty C96 turbine, the study predicts stresses and acceptable crack sizes for different damage scenarios. The resulting tool helps operators assess blade integrity after inspection, reducing downtime and improving maintenance decisions across the wind energy industry.

For more details

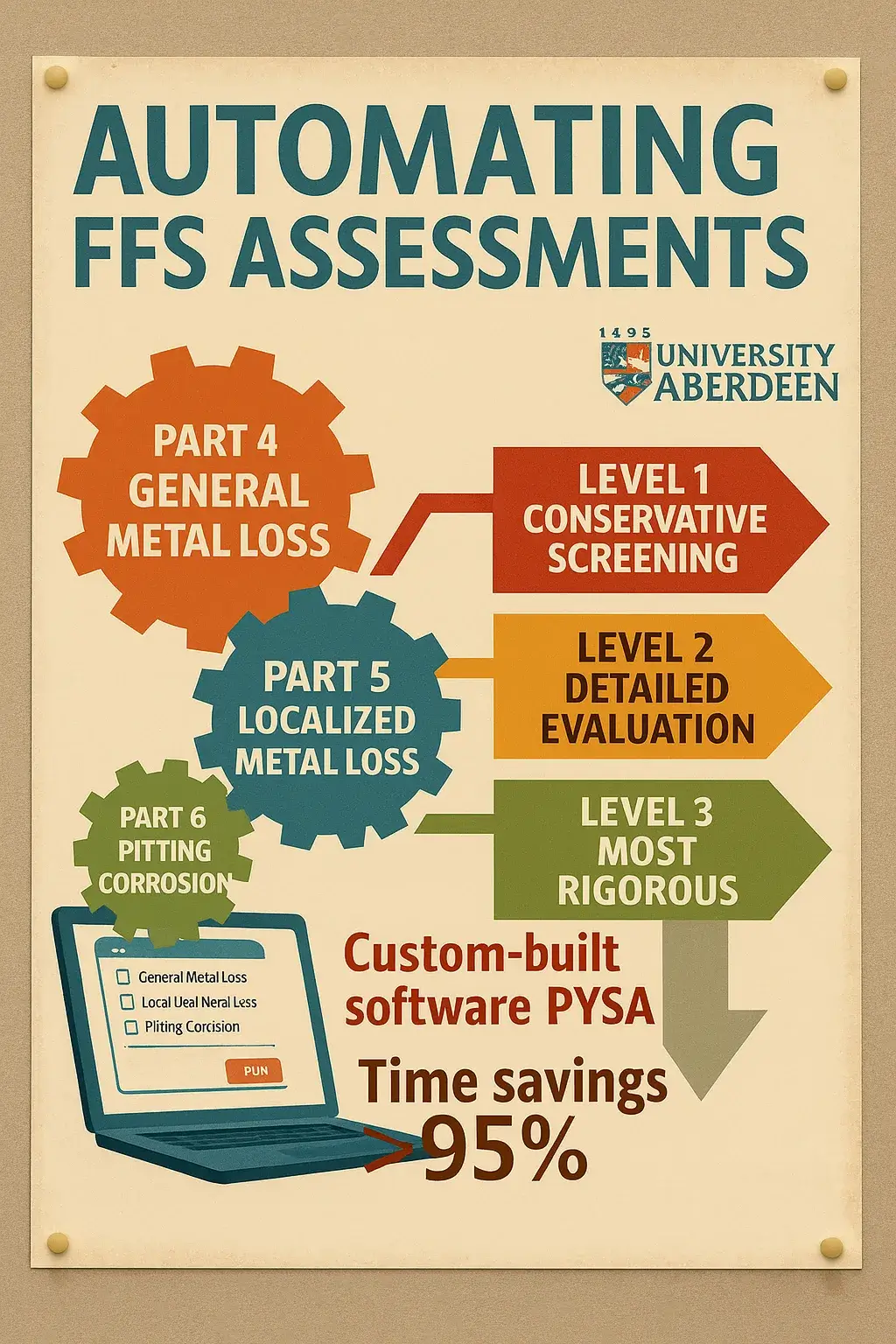

Automating Fitness-for-Service (FFS) Assessments through Intelligent Computation

Our custom-built software PYSA automates API 579-1/ASME FFS-1 Parts 4–6 for general, localised, and pitting metal loss. Covering Levels 1–3 assessments, it delivers up to 95% time savings, consistent results, and smarter integrity evaluations — advancing digital automation in Fitness-for-Service analysis at the University of Aberdeen.

For more details

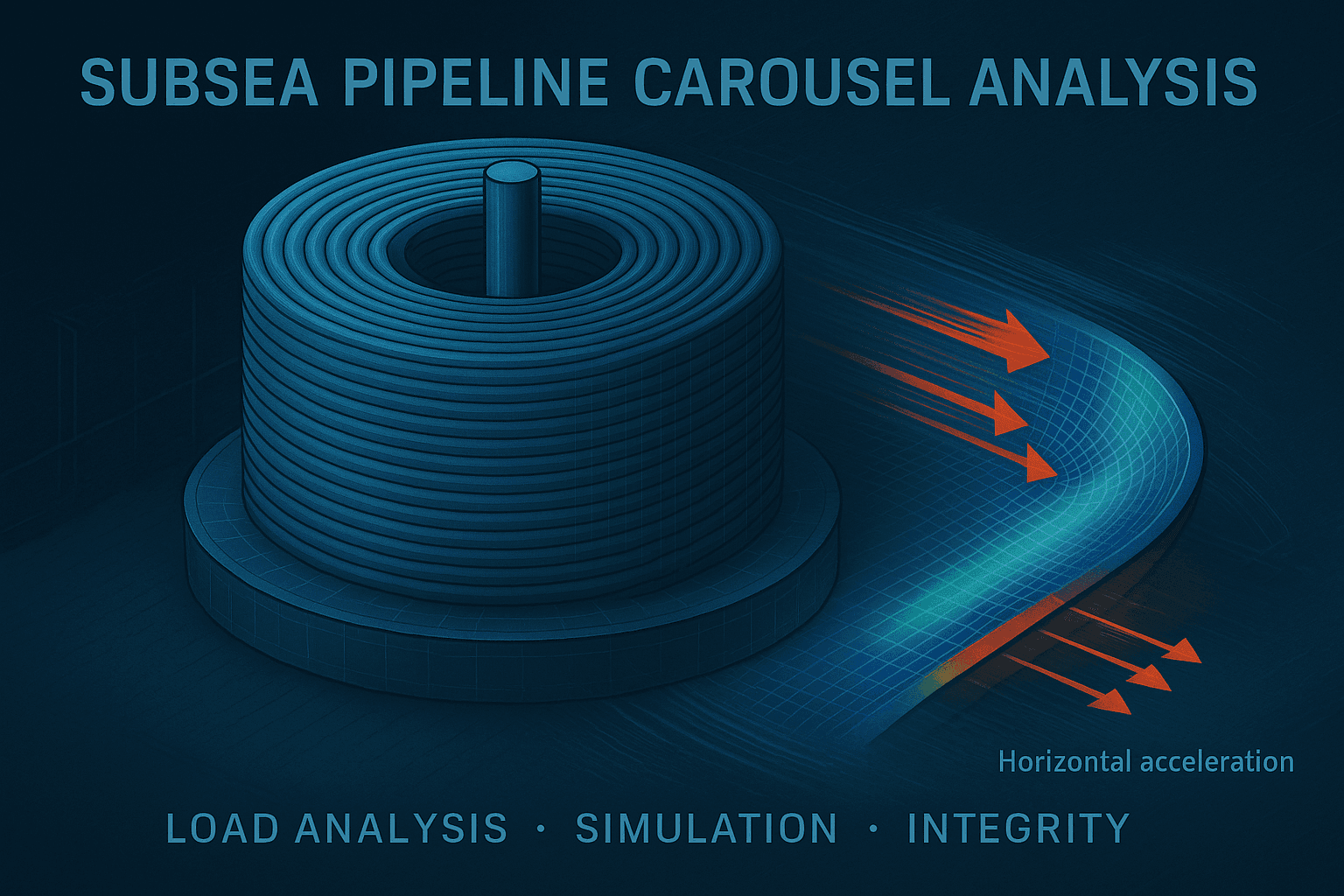

Subsea Pipeline Carousel Analysis

This project investigates the mechanical behaviour of subsea pipeline carousels during storage and transport. Using ABAQUS simulations, the study models the distribution of forces, pressures, and deformations within the carousel’s base, core, and spooled product under varying gravity and horizontal accelerations. The results identify critical stress regions and inform safer, more efficient designs for offshore pipeline handling systems.

For more details

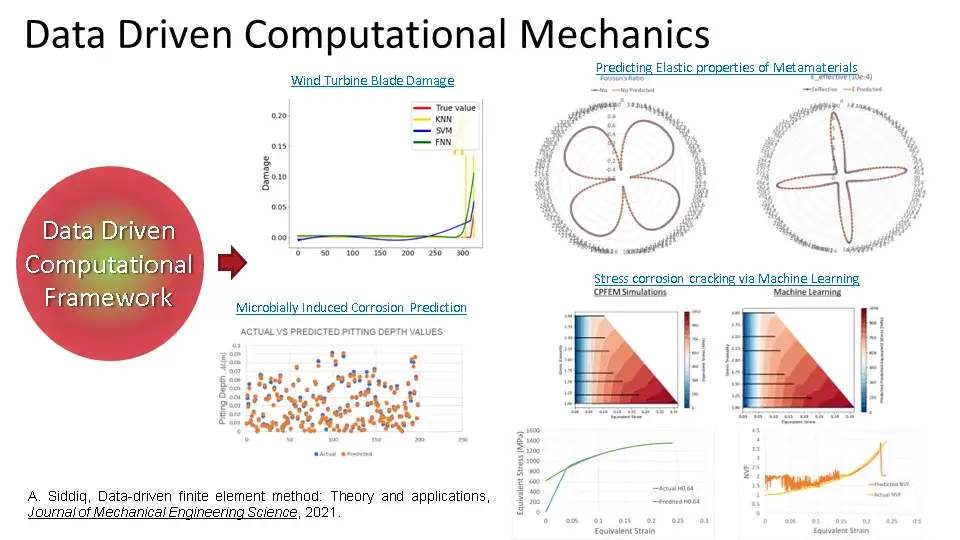

AI/ML based Engineering Projects

This research integrates data science and machine learning with computational mechanics to enhance material behaviour prediction and structural integrity assessment. The Data Driven Computational Framework connects experimental data, finite element simulations, and AI-based models to predict complex phenomena such as wind turbine blade damage, elastic properties of metamaterials, corrosion behaviour, and stress corrosion cracking. This approach accelerates discovery, improves prediction accuracy, and bridges physics-based and data-driven methods for next-generation engineering design.

For more details

Machine Learning-Assisted Wind Farm Design

This study combines heuristic optimization with machine learning and pattern recognition to accelerate wind farm layout prediction. Using a novel Scaled Layout Kernel (SLK) approach, it reproduces optimized turbine arrangements 100,000 times faster than traditional methods, with comparable accuracy. The framework demonstrates how data-driven modelling can guide efficient, sustainable wind energy design without relying on full-scale AI optimization.

For more details

Buckling of Subsea Pipelines

This project investigates the lateral buckling behaviour of subsea pipelines under high-pressure, high-temperature (HPHT) conditions using finite element simulations in ABAQUS. The study compares pipe and shell elements, validating results against Hobbs’ analytical method, and explores how soil friction, diameter-to-thickness ratio, and initial imperfection affect stability. The findings help improve the design and safety of offshore pipelines by identifying key parameters influencing buckling resistance.

For more details

Analytical Tool for Pipeline Walking

This project developed and validated an analytical tool for rapid assessment of pipeline walking in high-pressure, high-temperature offshore pipelines. The tool predicts axial displacement due to thermal transients and seabed slopes, enabling quick screening before detailed finite element analysis. Validation against industry FEA results from the Baleine field confirmed strong accuracy within analytical limits, providing engineers a fast and practical method for early design evaluation.

For more details

MLBUCKLIZER: Predicting Post-Buckling Pipeline States

This project developed MLBUCKLIZER, a Python-based platform integrating finite element modelling and machine learning to predict the post-buckling behaviour of subsea pipelines. The tool automates data generation, extraction, and learning directly from ABAQUS simulations, enabling rapid assessment of stress, strain, and failure indicators after buckling. By linking physics-based models with predictive AI, MLBUCKLIZER accelerates integrity evaluation and decision-making for safe offshore pipeline operations.

For more details